Lightning is a typical electrical discharge phenomenon in Nature accompanied by a flash of light and the crash of thunder. Normally a gas, such as air, does not conduct electricity. However, when conditions are right, an electrical current can flow through the air, which is called a discharge. This phenomenon is accompanied by a bolt of lightning (light and heat) and a roll of thunder (sound and pressure).

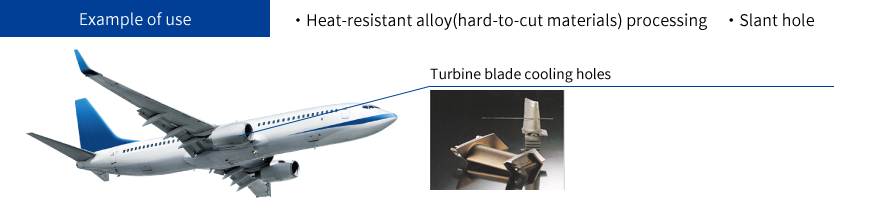

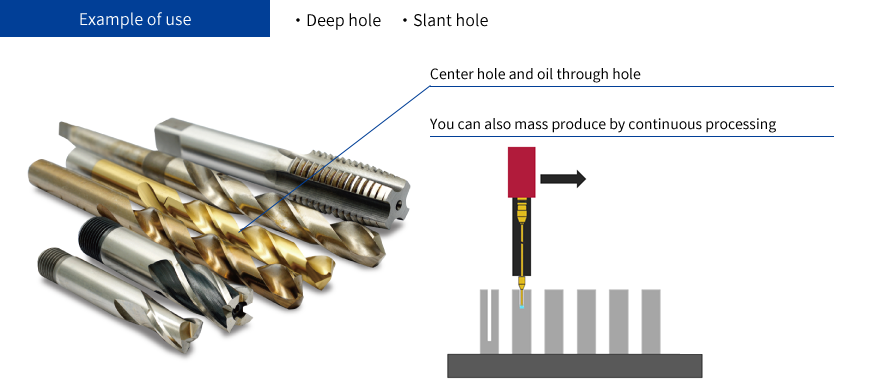

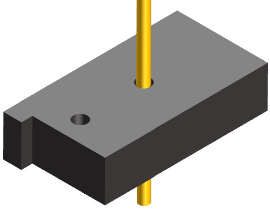

In electrical discharge machining (EDM), a very small “lightning bolt” or spark is created between the electrode and the workpiece many hundreds to thousands of times per second. A hole is made by repeatedly melting the workpiece at this point of electric discharge and blowing away the molten material by pressure. For this reason, this method allows for machining hard-to-cut materials and creating extremely deep holes, which is difficult to do by drilling, as far as the material is electrically conductive. Because it is non-contact machining, it is also good at machining a spherical object and making a hole obliquely.

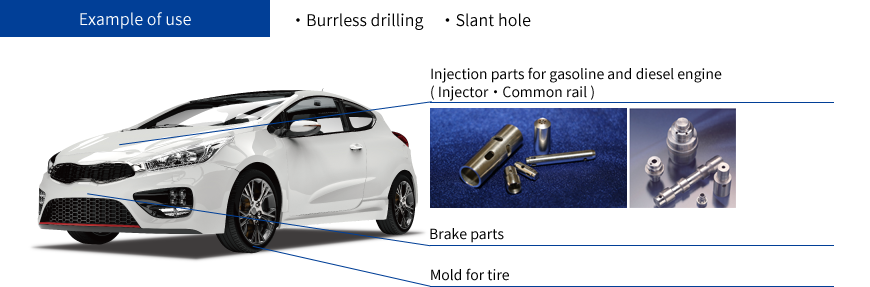

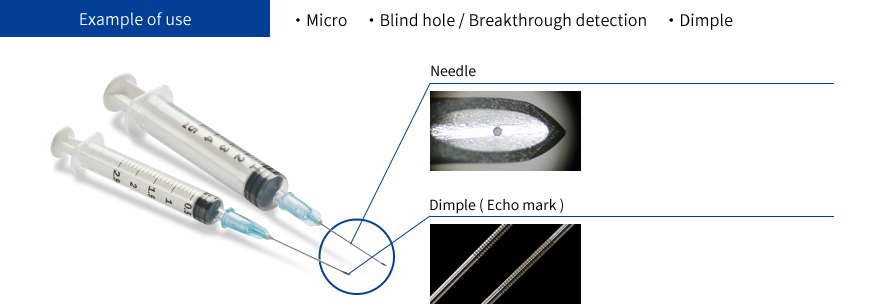

The small-hole EDM machine is a machine tool that is good at forming small holes with a diameter of 3 mm or smaller. It jets a liquid out of a pipe-shaped electrode, and its liquid pressure removes machining chips to increase the machining speed significantly. In addition, burrs, which are a concern with drilling, are rarely generated, allowing the process of removing burrs to be eliminated.

EDM is acknowledged as a machine tool that enables burrless mass-production of components in various industries, such as automobiles, aircraft, medical equipment, and semiconductors.

The wire EDM machine is a machine tool that uses extremely thin wires with a diameter of 0.3 mm or thinner. It generates discharge between the wire and the workpiece and cuts the workpiece into various shapes, similar to using a fret saw.

After cutting, rubbing the side faces of the workpiece three or four times repeatedly can improve the surface roughness.

This equipment is often used to manufacture molds for presswork.

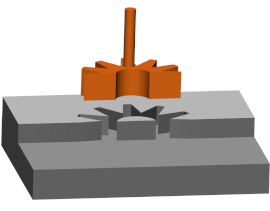

The diesinking EDM machine is a machine tool that transforms various shapes of electrodes to metal workpieces inside a processing liquid.

Although making electrodes involves costs, this equipment is often used to manufacture molds for molding resin, because it can process complicated shapes.

In general, when trying to make a hole, people may think of drilling. The small hole EDM machine can perform special machining that is difficult for drills and high-precision machining.

- Making a start hole to put a wire through.

- Machining where the generation of burrs is strictly prohibited.

- Machining hard-to-cut materials such as hardened steel, hard metal alloy, tungsten, titanium, and molybdenum.

- Machining holes with a high aspect ratio such as L/D = 1500.

- Machining curved surfaces, spherical objects, and slopes, which may generate burrs.

ASTEC's small-hole EDM machine is being used in various industries under the themes of "burrlessness," "small-diameter deep holes," "hard-to-cut materials" and "automation."

We solve problems such burrs and drill breakages due to machining with products that emphasize users' way of thinking.

・Eliminates deburring work by suppressing the generation of burrs・・・

CNC high-speed small-hole EDM : A22M

・Machining curved surfaces and slopes smoothly・・・

CNC high-speed small-hole EDM : A22T

・Machining hard-to-cut materials such as hardened steel and hard metal alloys・・・

CNC high-speed small-hole EDM : A33M

・Machining holes with a high L/D (aspect ratio)・・・

High-speed small-hole EDM unit : 6Z1800

・Making inline factory automation linking with robots・・・

High-speed small-hole EDM unit : 2Z080

・Continuous operation and labor saving by NC・・・

CNC high-speed small-hole EDM : A33CNC

・Machining fine precision holes with a diameter of 0.1 mm or smaller・・・

CNC high-speed micro-hole EDM : A11MP1CNC