1. Fine hole machining

Ultra-speed machining of fine holes. Minimum diameter: 0.04 mm. Astec’s original machining technology, with domestic/international patents, enables machining large numbers of fine holes at an overwhelming speed.

[Machining data]

- Depth : 5.0mm

- Hole diameter : φ0.13

- Machining time : 67 s

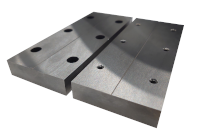

Image 1SUS304

- Depth : 0.2mm

- Hole diameter : φ0.04

- Machining time : 4 s

Image 2SUS304

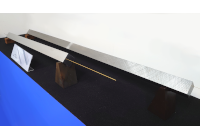

2. Generating fine machining

This method can make fine holes with a variety of shapes by lowering the electrode and moving it in arbitrary directions. One unit can perform multiple machining processes, which helps save space and achieve high cost-performance.

[Machining data]

- Depth : 1.0mm

- Hole diameter : φ0.25*0.10

- Machining time : 26 s

Image 3SUS430

3. Ultra-deep fine hole machining

6Z1800 excels at machining deep holes that are difficult to bore for cutting machining. Using an electrode with a length of up to 1,800 mm, it can machine through holes with a diameter of 1 mm and a maximum length of 1,500 mm. Its special middle swing stopper suppresses swings of the electrode when it rotates, ensuring stable machining with vertical accuracy.

[Machining data]

- Depth : 1,500mm

- Hole diameter : φ1.0

- Machining time : 89 min 15 s

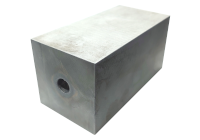

Image 5Hardening of SKD11

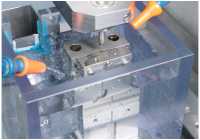

4. Ultra-hard deep hole machining

Machining fine and deep holes in hard-to-cut materials. Astec pursues machining ultra-hard materials that are said to be difficult to process. Based on our original technology and experience, we are expanding the possibilities of fine hole EDM machines, from a diameter of 0.5 mm to that of 9.0 mm.

[Machining data]

- Depth : 150mm

- Hole diameter : φ0.5

- Machining time : 169 min 35 s

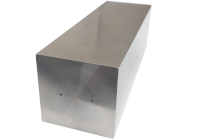

Image 6Carbide SA180

- Depth : 100mm

- Hole diameter : φ9.0

- Machining time : 510 min

Image 7Carbide G6

5. Machining large deep holes on hard-to-cut materials

Machining hard-to-cut materials, such as Inconel, aluminum, titanium, and stainless steel, which are hard to machine with a gun drill. The small-hole EDM machine, which can process any electrically conductive materials, can machine deep holes in hard-to-cut materials.

[Machining data]

- Depth : 400mm

- Hole diameter : φ9.32

- Machining time : 2 h 16 min

Image 8 upper leftInconel

- Depth : 400mm

- Hole diameter : φ9.27

- Machining time : 6 h 20 min

Image 8 upper right Pure titanium

- Depth : 400mm

- Hole diameter : φ9.35

- Machining time : 1 h 20 min

Image 8 lower leftAluminum

- Depth : 400mm

- Hole diameter : φ9.90

- Machining time : 13 h 20 min

Image 8 lower rightSUS420J2

6. Non-discoloring machining of titanium

With the new type of power supply now under development, discoloration that occurs during the machining of titanium can be minimized. Machining deep holes can be performed without discoloration. The difference between conventional and new power supplies is evident in the degree of discoloration.

This new type of power supply applies to all the EDM machines.

[Machining data]

- Depth : 150mm

- Hole diameter : left φ1.50, right φ1.25

- Machining time : 10 min 50 s for the left, 10 min 31 s for the right

Image 964 titanium

7. Machining next-generation compound semiconductors

Astec is actively conducting research of machining next-generation compound semiconductors, such as silicon carbide (SiC) that is used for home energy management systems (HEMS) and electric vehicles (EVs), and gallium nitride (GaN) used for power sources/chargers of 5G or other base stations.

[Machining data]

- Depth : 11mm

- Hole diameter : φ0.45-0.44

- Machining time : 19 s

Silicon carbide (SiC)

- Depth : 0.45mm

- Hole diameter : φ0.099-0.108

- Machining time : 2 s

Gallium nitride (GaN)

- Depth : 0.45mm

- Hole diameter : φ0.51-0.52

- Machining time : 10 s

8. Machining special materials

We are also conducting research on machining materials with special properties.

When machining neodymium or samarium-cobalt magnets with a drill, drill blades tend to be damaged and they may be cracked or chipped. The small hole EDM machine can process these materials with no problems because it performs non-contact machining. Processing magnesium requires special caution because its cut chips easily ignite. Immersion EDM solves this problem. (Image 12)

Although it has not been possible to machine nonconductive ceramics, our EDM will attempt to machine electrically conductive ceramics. We will explore various possibilities for EDM.

[Machining data]

- Depth : 50mm

- Hole diameter : φ0.45

- Machining time : 7 min

Neodymium

- Depth : 50mm

- Hole diameter : φ0.95

- Machining time : 8 min

- Depth : 38mm

- Hole diameter : φ1.0

- Machining time : 6 min

Samarium-cobalt magnet

- Depth : 100mm

- Hole diameter : φ2.0

- Machining time : 1 min 30 s

Image 13

Magnesium

- Depth : 3mm

- Hole diameter : φ0.128-0.178

- Machining time : 36 s

Image 14

NPZ-28 Conductive ceramic

9. Dimple machining

Dimple machining is used for decreasing frictional resistance, improving the durability of lubricant oils, reducing adhesion of cut-chips/sludge, and improving maintainability such as increasing cleaning power. Dimple-machined surfaces are used for ultrasonic position detection and other functions. Astec has achieved the ultra-high-speed dimple machining required in a wide range of industries.

[Machining data]

- Outer diameter of pipe : φ1.0

- Depth : 0.1mm

- Hole diameter : φ0.1

- Number of machined dimples : 390

- Machining time : 15 min 45 s; 2.423 s per dimple

Image 15SUS440C