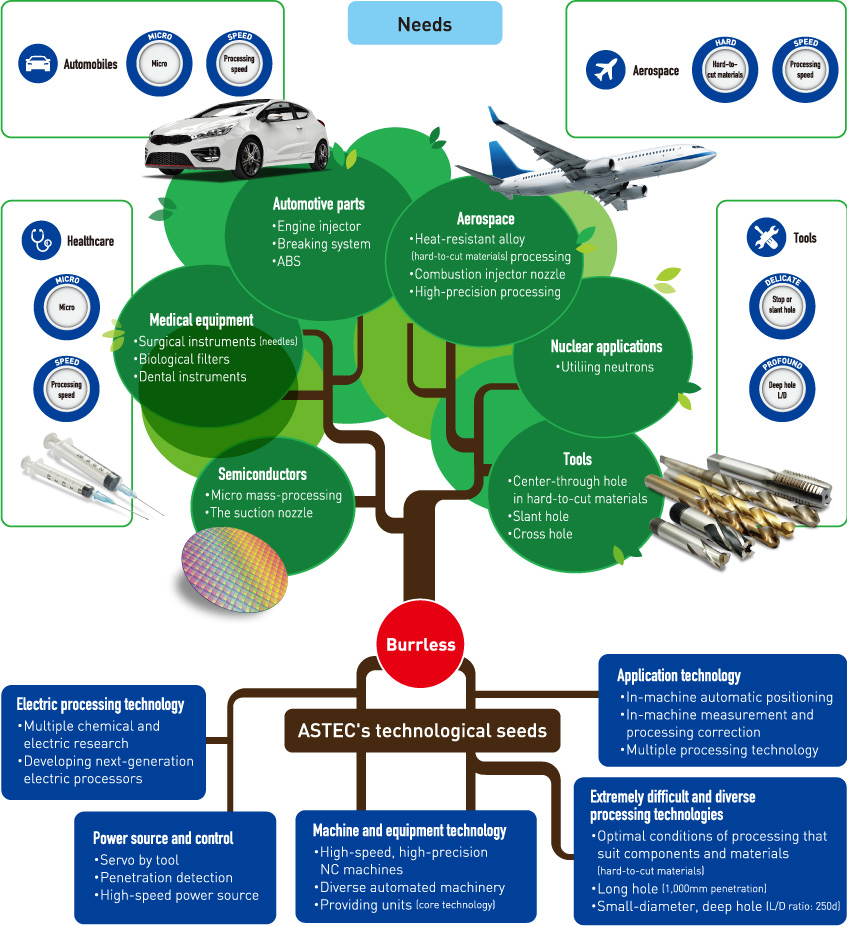

ASTEC's processing technology has solved difficult problems that occurred in various industries.

Going forward, ASTEC will leverage its unique know-how to respond to customer requirements pertaining to the trend to process harder, lighter and smaller parts.

ASTEC's principles of processing, unlike cutting, is to process metal using electrodischarge thermal fusion.

Features

Non-contact processing / It can be processed to spherical or curved surface

Processing using electrical energy / We can process hardened steel and carbide etc.

We can do a difficult processing

Your process will be able to complete a drilling processing without burr.

High precision micro-hole machining

In the micro area processing is possible

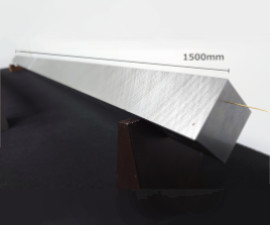

Amazing deep-hole processing

L/D ratio 1,500

Overwhelming speed

Supports mass production parts in the micro processing area

Facing today's challenges in micromachining

(obtaining domestic and international patents)

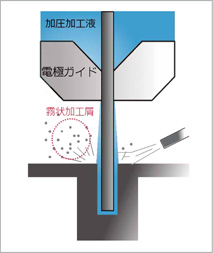

In electrodischarge processing in the micromachining area-unlike conventional small-hole drilling-it was impossible to discharge burrs from inside the electrode using liquid pressure because it was difficult to make pipe-shared electrodes.

ASTEC solved this problem by developing a micromachining electrode guide, with flush jets allowing processing using the level of power that would normally burn the electrode. This increases the processing speed even further.